QH7 Series

Portable "Heavy-Duty" Hardness Tester

Leeb + UCI

Leeb and or UCI to control all sorts of metal parts.

Cover the widest range of applications combining Leeb and UCI methods of hardness testing. Measure small parts with UCI and get faster and accurate measures in Leeb with our GyroTag technology that automatically corrects the impact angle.

A robust design in a high resistance aluminum enclosure with a large display and the ability to support all impact device types and UCI probes makes the QH7 Series the most complete and advanced option in the dmq QH Family of portable metal hardness testers.

QH7

Outstanding features

Measure with the Leeb or rebound method 1

Measure with the UCI method 1

GyroTag: Auto impact device angle detection

Accepts all impact device types

Accepts 10, 50 and 98N UCI probes

Measures in the most popular units

Generate user materials

Sound and visual alarms for maximum and minimum

High resistance aluminum enclosure

Operates on rechargeable batteries

Memory for 32000 readings

USB and RS232 for data transfer

Real time histogram graphics

Real time complete statistics

Meets international standards

5 year limited warranty on the electronic unit

1. Depending on model. See the Models section.

Impact devices with GyroTag

We offer impact devices that are application specific and include GyroTag technology.

Impact devices with GyroTag

We offer impact devices that are application specific and include GyroTag technology.

Type G impact device

A greater impact energy allows measurements on rough surfaces with little preparation. Recommended for large, founded and forged parts.

Type DL impact device

Features a 50mm long tip and 4mm diameter making it ideal to measure in hard to reach places such as grooves and gears.

Type D impact device

General use impact device that offers the widest ranges in all hardness units and available materials.

Type D impact device comes standard with the QH7 L and QH7 C models.

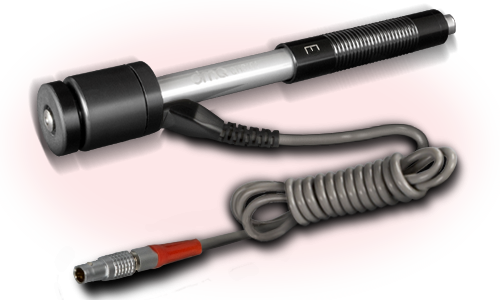

Type E impact device

Uses a synthetic diamond ball allowing high hardness measurements (up to 1200HV). This is the best option to measure hardened steel or parts with similar treatments.

Type C impact device

A low impact energy that also produces a smaller indentation makes this impact device ideal for superficial heat treatment and small part measurements.

Type DC impact device

Type D impact device with a short body that is ideal for measurements in reduced spaces.

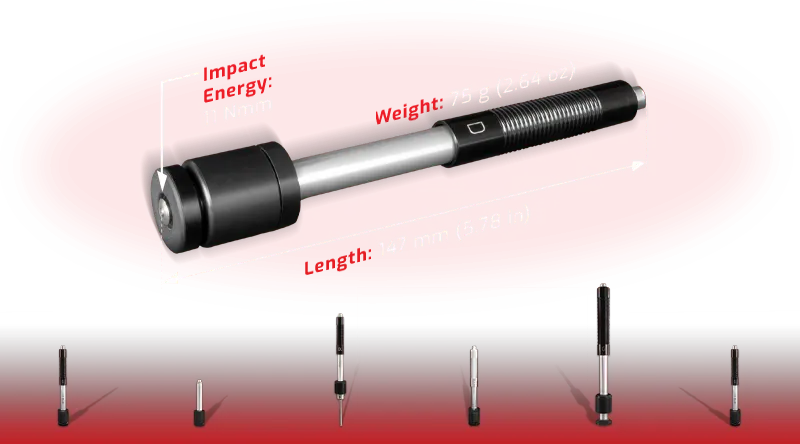

Type D

impact device

General use impact device that offers the widest ranges in all hardness units and available materials.

Type D impact device comes standard with the QH7 L and QH7 C models.

Impact energy: 11Nmm

Length: 147mm / 5.78in

Weight: 75g / 2.64oz

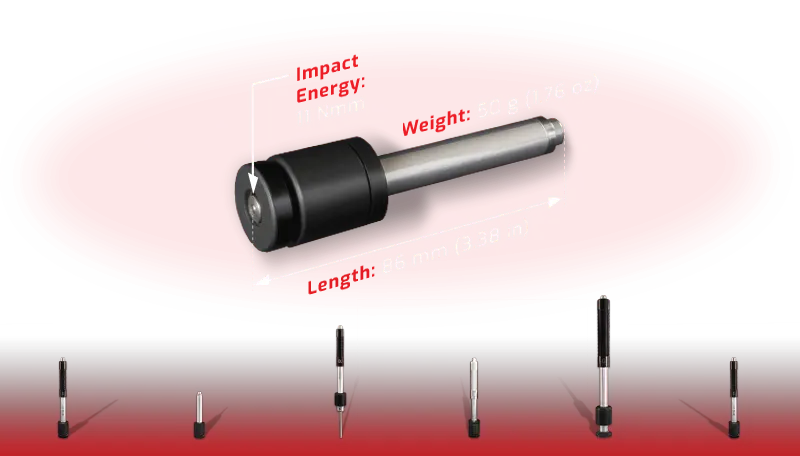

Type DC

impact device

Type D impact device with a short body that is ideal for measurements in reduced spaces.

Impact energy: 11Nmm

Length: 86mm / 3.38in

Weight: 50g / 1.76oz

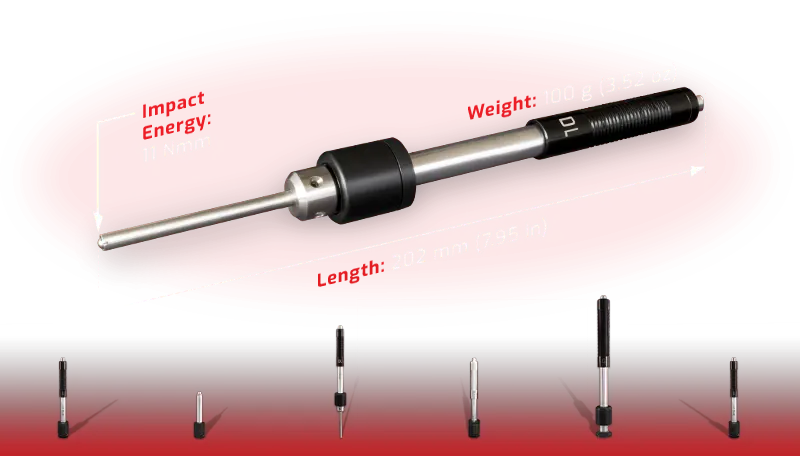

Type DL

impact device

Features a 50mm long tip and 4mm diameter making it ideal to measure in hard to reach places such as grooves and gears.

Impact energy: 11Nmm

Length: 20 2mm / 7.95in

Weight: 100g / 3.52oz

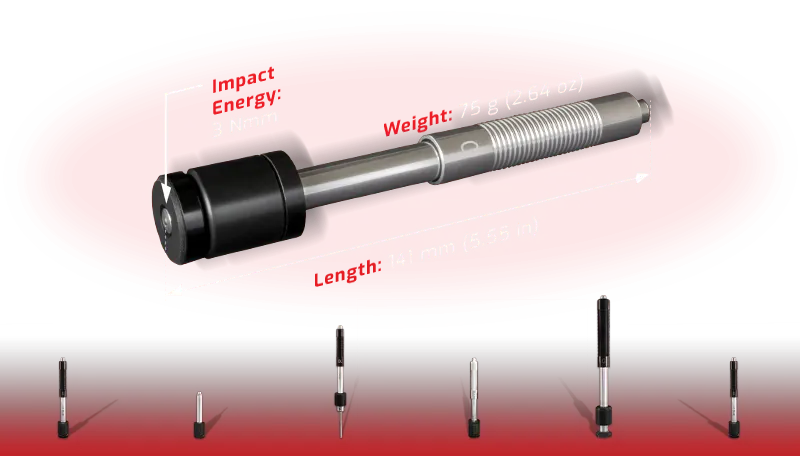

Type C

impact device

A low impact energy that also produces a smaller indentation makes this impact device ideal for superficial heat treatment and small part measurements.

Impact energy: 3Nmm

Length: 141mm / 5.55in

Weight: 75g / 2.64oz

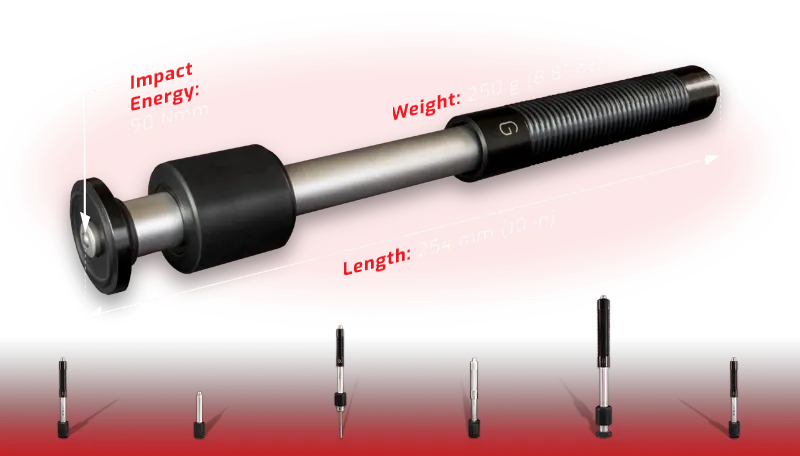

Type G

impact device

A greater impact energy allows measurements on rough surfaces with little preparation. Recommended for large, founded and forged parts.

Impact energy: 90Nmm

Length: 254mm / 10in

Weight: 250g / 8.81oz

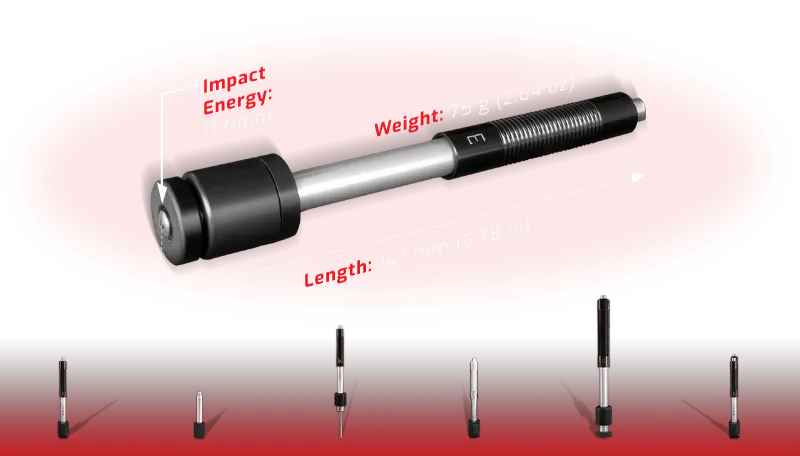

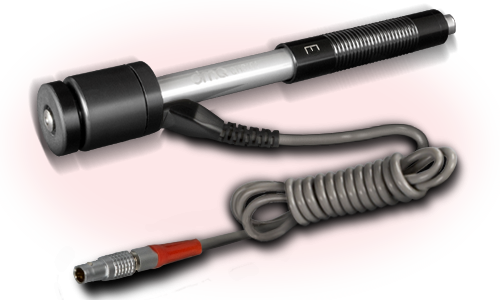

Type E

impact device

Uses a synthetic diamond ball allowing high hardness measurements (up to 1200 HV). This is the best option to measure hardened steel or parts with similar treatments.

Impact energy: 11Nmm

Length: 155mm / 6.10in

Weight: 80g / 2.82oz

GyroTag Technology

Exclusive in the 7 Series

GyroTag technology combines automatic impact device angle detection and correction. Both will make your job easier and faster with guaranteed accuracy in your measurements, even when changing impact devices.

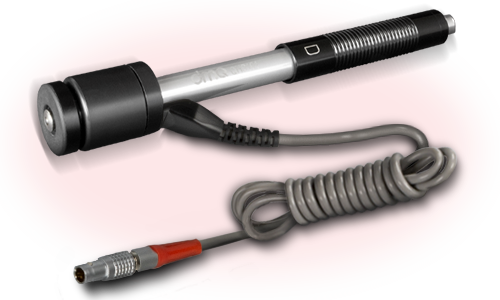

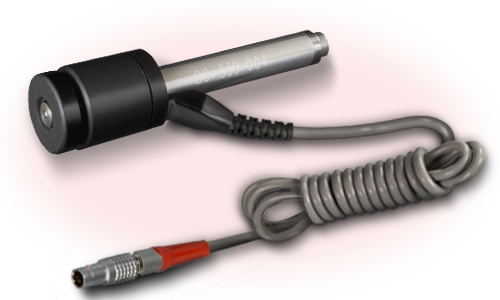

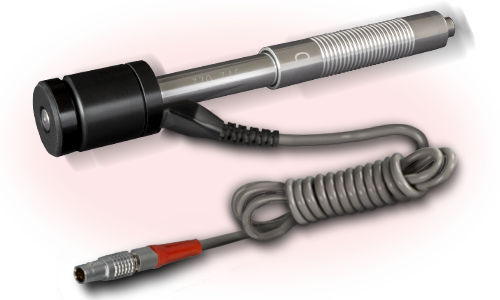

UCI Probes

UCI probes are ideal for hardness measurements of small and thin parts and of superficial hardness. They are available in three test loads and choosing the right load depends on the surface finish (roughness) of the test piece that you need to control.

Also included with all UCI probes is CalTag technology which is intregrated calibration for guranteed accuracy

Select a UCI probe to view additional information.

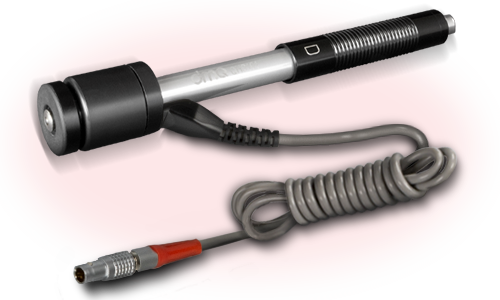

10N UCI Probe

Ideal to measure superficial hardness, polished surfaces and small parts with a good finish.

Superficial roughness:

Maximum roughness is Ra 5µm according to ASTM 1038 standard

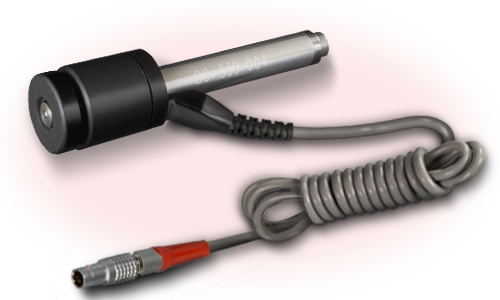

50N UCI probe

Measure induction or cemented treated parts such as crankshafts, gears, welds and heat affected zones.

Superficial roughness:

Maximum roughness is Ra 10µm according to ASTM 1038 standard

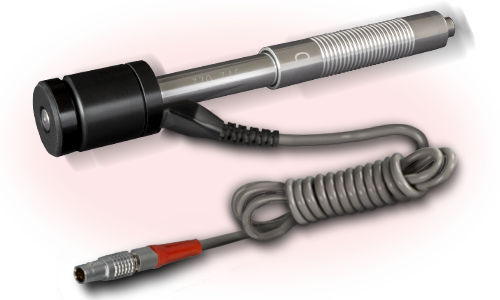

98N UCI probe

Recommended for use in founded parts, weld seams and heat affected zones even in unmachined surfaces.

Superficial roughness:

Maximum roughness is Ra 15µm according to ASTM 1038

10N UCI Probe

Ideal to measure superficial hardness, polished surfaces and small parts with a good finish.

Superficial roughness: Maximum roughness is Ra 5µm according to ASTM 1038 standard

50N UCI probe

Measure induction or cemented treated parts such as crankshafts, gears, welds and heat affected zones.

Superficial roughness: Maximum roughness is Ra 10µm according to ASTM 1038 standard

98N UCI probe

Recommended for use in founded parts, weld seams and heat affected zones even in unmachined surfaces.

Superficial roughness: Maximum roughness is Ra 15µm according to ASTM 1038 standard

Applications

Ideal for measurement and control of:

Slide the table horizontally to fully display its content.

|

QH7 L |

QH7 U |

QH7 C |

|

|---|---|---|---|

| Massive parts | |||

| Founded, forged or rough finished parts | |||

| Steel and aluminum alloys | |||

| HAZ (Heat Affected Zones) or TAZ (Thermally Affected Zones) in welds | |||

| Metal plates and sheet metal coils | |||

| Irregular surfaces | |||

| Thin parts | |||

| Heat treated or superficial treatments |

Not recommended

Depends on the part

Adequate use

Models

|

Models |

Leeb (Rebound) Leeb |

UCI (Ultrasonic Contact Impedance) UCI |

|---|---|---|

| QH7 L | ||

| QH7 U | ||

| QH7 C |

NOTE: Rebound models are delivered with a type D impact device.

Ask for other impact devices.

Compatible with DataCenter

All models allow you to connect to a PC where data can be processed using our dmq DataCenter software available at no cost.

See DataCenterModel upgrades

Have your needs changed after you purchased the instrument?

You can upgrade the model of your instrument to add the features that you need with our model upgrade licenses.

Request model upgradeQH7 Series general specifications

Dimensions

197 x 111 x 65mm

(7.7 x 4.4 x 2.6in)

Weight (with batteries)

998g

(2.20lbs)

Resolution / Hardness units

Leeb (HL)

Vickers (HV)

Brinell (HB)

Rockwell B (HRB)

Rockwell C (HRC)

Shore (HS)

Mechanical strength (N/mm2)

User units 2

Materials

Steel

Grey Cast Iron

Nodular Cast Iron

Aluminum

Brass

Copper

Bronze

Power

AA x 2 de Ni-MH rechargeable by USB

Battery Life

70 Hours 3

Certificates and International Standards

Certificate of Conformity

CE Marking

ASTM A956 (LEEB)

ASTM A1038 (UCI)

ASTM E140 (UCI)

Energy absorbed on impact (Leeb)

Resolution

1HL

1HB

1HV

0.1HRC

0.1HRB

0.1HS

1N/mm2 (Mechanical Strength)

Accuracy

±4HL (0.5% at 800HL)

Measuring Range

HL 150 - 960

Ultrasonic Contact Impedance (UCI)

Resolution

1HV

0,1HRC

0,1HRB

1HB

0,1HS

1N/mm2 (Mechanical Strength)

Accuracy

±5% in the entire HV measuring range

Measuring Range

HV 100 - 950

2. User can set units for measuring materials not included in equipment list.

3. Display light off.

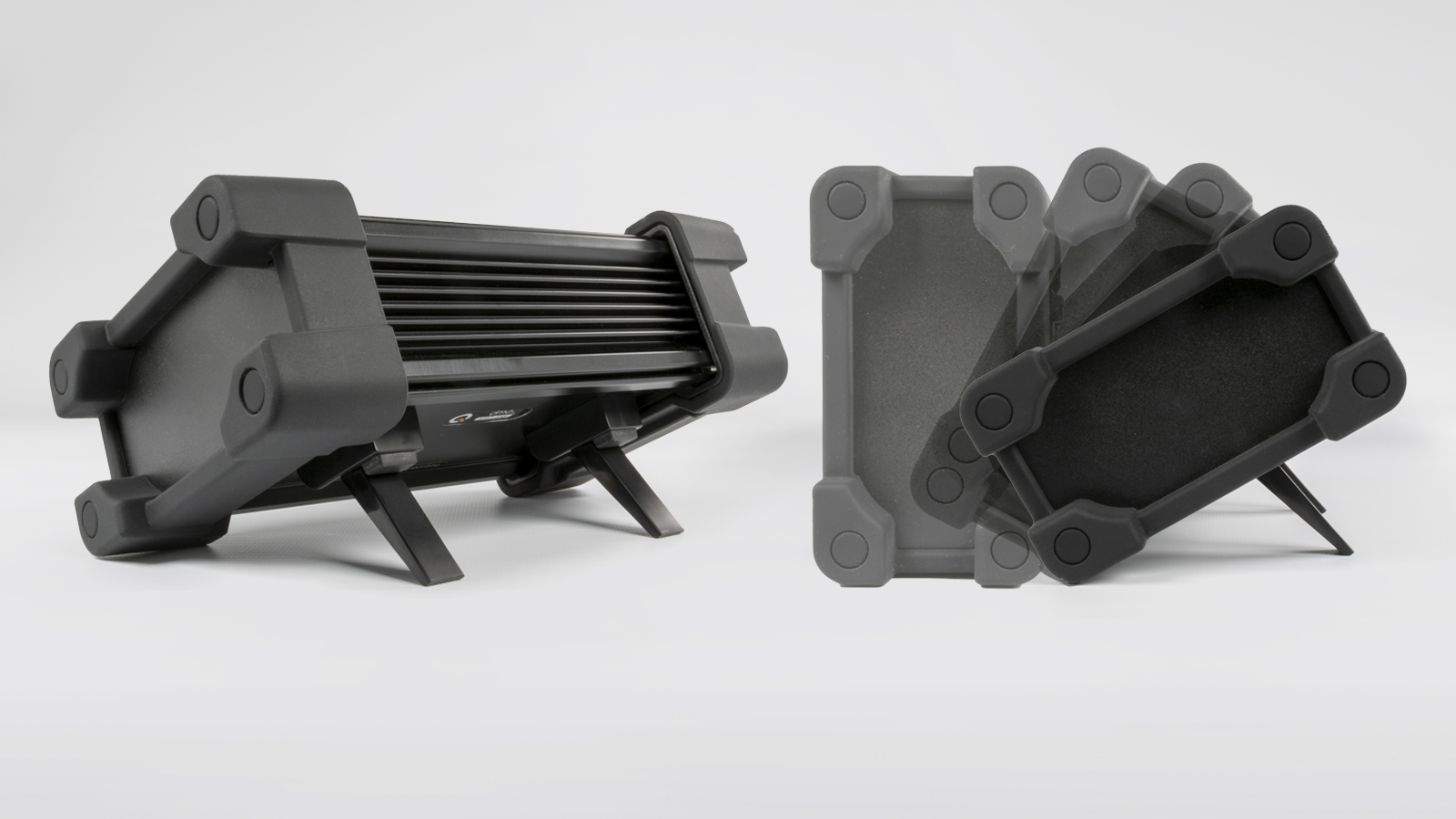

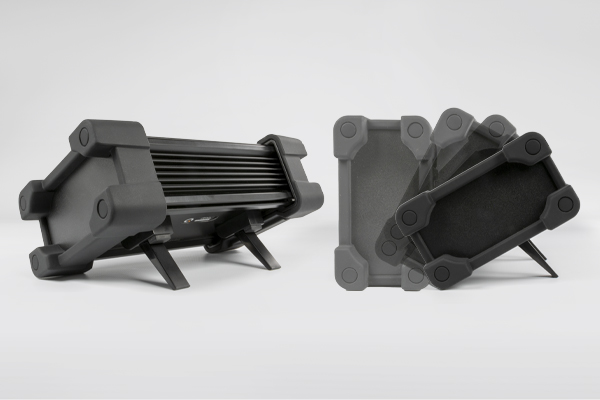

Ready to use

Delivered in a high impact carrying case, inside you will find:

- QH7 electronic unit

- Coupling paste for parts

- Impact device 4

- Battery charger

- UCI probe 5

- USB cable to connect to a PC

- Pendrive with dmq DataCenter software and user manual

- Reference test block 6

- Certificate of conformity

4. In QH7 L and QH7 C model / 5. In QH7 U and QH7 C models / 6. Depends on the model

Hardness measurements with the LEEB method - QH7 L

Hardness measurement with the UCI method - QH7 U

Hardness measurements with both LEEB and UCI - QH7 C

What's inside the QH7 C

What's inside the QH7 L

What's inside the QH7 U

QH7 electronic unit - Front and Back

QH7 electronic unit - Sides and connectors detail

QH7 electronic unit - Tilt Feet

You can find more videos in our YouTube channel.

Go YoutubeAccessories and Consumables

QHS102

Type D impact device

General use impact device that offers the widest ranges in all hardness units and available materials.

Impact energy: 11Nmm

Length: 147mm / 5.78in

Weight: 75g / 2.64oz

QHS202

Type DC impact device

Type D impact device with a short body that is ideal for measurements in reduced spaces.

Impact energy: 11Nmm

Length: 86mm / 3.38in

Weight: 50g / 1.76oz

QHS302

Type DL impact device

Features a 50mm long tip and 4mm diameter making it ideal to measure in hard to reach places such as grooves and gears.

Impact energy: 11Nmm

Length: 202mm / 7.95in

Weight: 100g / 3.52oz

QHS502

Type C impact device

A low impact energy that also produces a smaller indentation makes this impact device ideal for superficial heat treatment and small part measurements.

Impact energy: 3Nmm

Length: 141mm / 5.55in

Weight: 75g / 2.64oz

QHS602

Type G impact device

A greater impact energy allows measurements on rough surfaces with little preparation. Recommended for large, founded and forged parts.

Impact energy: 90Nmm

Length: 254mm / 10in

Weight: 250g / 8.81oz

QHS702

Type E impact device

Uses a synthetic diamond ball allowing high hardness measurements (up to 1200 HV). This is the best option to measure hardened steel or parts with similar treatments.

Impact energy: 11Nmm

Length: 155mm / 6.10in

Weight: 80g / 2.82oz

QHS110

10N UCI Probe

Ideal to measure superficial hardness, polished surfaces and small parts with a good finish.

Superficial roughness: Maximum roughness is Ra 5µm according to ASTM 1038 standard

QHS150

50N UCI probe

Measure induction or cemented treated parts such as crankshafts, gears, welds and heat affected zones.

Superficial roughness: Maximum roughness is Ra 10µm according to ASTM 1038 standard

QHS198

98N UCI probe

Recommended for use in founded parts, weld seams and heat affected zones even in unmachined surfaces.

Superficial roughness: Maximum roughness is Ra 15µm according to ASTM 1038 standard

QHX102

Impact Body

Consult for impact device model.

QHA012

Set of 12 support rings to measure concave and convex surfaces

Compatible with type D, DC, C and E impact devices.

QHG005

Coupling paste 50cc / 1,76oz

Coupling paste for use with lightweight parts.

Calibration and Traceability certificates available for reference test blocks. See Certifications section.

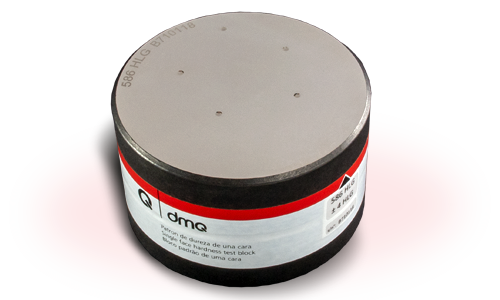

HLD reference test block

Type Leeb reference test block

Diameter: 90mm

Height: 56mm

Weight: 2.9kg

Hardness: 740 a 790HLD ±6HLD

- QHR101: For D, DC impact devices

- QHR102: For DL impact device

- QHR103: For C impact device

HLG reference test block

Type Leeb reference test block

Diameter: 150mm

Height: 90mm

Weight: 5.8kg

Hardness: 460 a 550HLG ±12HLG

HB, HRB, HRC and HV reference test blocks

- QHR201: Rockwell C (HRC) reference test block

- QHR301: Rockwell B (HRB) reference test block

- QHR401: Brinell (HB) reference test block

- QHR501: Vickers (HV) reference test block

Inquire.

YAMAMOTO brand test blocks

- YHR201: Rockwell C test blocks (HRC)

- YHR301: Rockwell B test blocks (HRB)

- YHR401: Brinell test blocks (HB)

- YHR501: Vickers HV10 test blocks (HV)

Inquire.

QHC101

Cable with connector for all dmq impact devices

Compatible with all dmq impact devices and instruments.

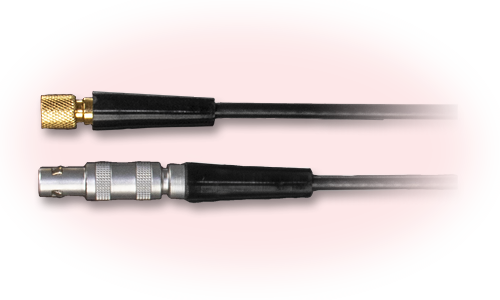

QHC105

Cable with connector for all dmq UCI probes

Cable with a Lemo 0B and a Microdot connector.

QAC001

Cable to connect a thermal printer to dmq instruments

Adapting cable with mini USB to mini USB connectors.

QAI001

Thermal printer for dmq instruments 7

Speed: 90mm/s

Resolution: 203dpi

Weight: 134g

Dimensions: 105 x 75 x 45mm

7. Does not include connecting cable

Certificates and International Standards

Included certificate

Certificate of Conformity

This certificate accompanies all DMQ equipment, they are made based on secondary reference test blocks, procedures and internal DMQ standards.

- QHF310: Certificate of Conformity for QH electronic unit with LEEB method on HLD test block

- QHF311: Certificate of Conformity for Electronic Unit with UCI method on Vickers test block

- QHF312: Certificate of Conformity for Electronic Unit with LEEB method + UCI method on HLD and Vicker test blocks

Optional certificates

Optionally, we offer Calibration certificates and Certificates with traceability for reference test blocks:

Calibration Certificate

Certificate issued by an external laboratory accredited by INTI-SAC, expressing the results of the calibration of the instruments or reference test blocks according to ISO/IEC 17025.

Check validity of the certifying organization in your region.

- QHF120: INTI-SAC Calibration Certificate under ISO/IEC 17025 IRAM 301 standard for HLD reference test block in HRC-HB or HV scale

- QHF121: INTI-SAC Calibration Certificate under ISO/IEC 17025 IRAM 301 standard for HV scale Vickers reference test block

Certificate with INTI-SAC Traceability

Additional certificate based on instruments or reference test blocks certified by INTI-SAC laboratory, a copy of the traceability certificates is attached to the traceability certificate.

Check validity of the certifying organization in your region.

- QHF220: Certificate with INTI-SAC Traceability for HLD reference test block on HRC scale

- QHF222: Certificate with INTI-SAC Traceability for Vickers reference test block on HV scale

International Standards

CE Marking

ASTM A956

Models: QH7 L, QH7 C

ASTM A1038 / ASTM E140

Models: QH7 U, QH7 C

I am Quokke, the  mascot.

mascot.

Choose us and be as happy as I am!

See products

QH7 Series

Portable "Heavy-Duty" Hardness Tester Leeb + UCI

Contact Us

Request Quotation